Offshore Racing Mainsail assembly

Portrait of a Class 40 Racing Mainsail

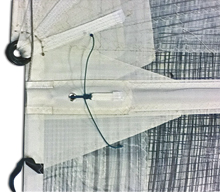

Textile leech batten box

This batten pocket with spectra lashing allows a broken batten to be removed from either the luff or the leech.

At the luff end, an Antal batten box allows the batten to be tensioned with an allen key.

The leech end opening can take rectangular battens.

Offshore racing halyard point

The halyard point is recessed (20cm) so that the mainsail can be hoisted to the masthead, thereby maximising the surface area.

The removable adjustable batten supports the roach and prevents it from inverting.

The batten’s horizontal adjustable lashing can increase its tautness rather like a bow. The head ring is secured with webbing strops spread over approximately 110° in order to absorb loads all the way up the luff to the roach.

The webbing is secured with hand-stitching to guard against tearing off under load.

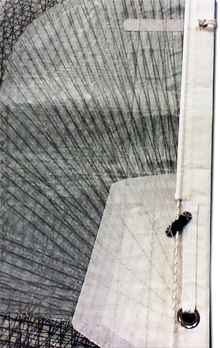

Inboard reef point

The reef reinforcement in radiating fibres (twaron) uses the same fibres as the mainsail.

All fibres are aligned along the load paths.

The leech line is led back along the luff so that it can be adjusted safely from the tack of the sail.

The aluminium cleat (chosen for its reliability and lightness) is hand-stitched with anti-UV thread.

The reef eyelet is secured with webbing to prevent slipping

Outboard reef point

The outboard reef point features an aluminium ring secured with webbing over approximately 90% to spread the loads. It is recessed into the sail for aerodynamic and aesthetic reasons.

The webbing is secured with hand-stitching to guard against the ring tearing off under load

The leech line, in spectra in this example, has been chosen for its resistance to abrasion and breakage.