Inshore Racing Mainsail assembly

High-tech manufacturing to maximize performances

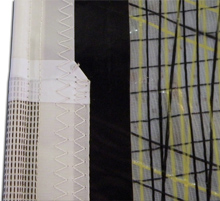

On this maisail - see opposite photo - the fibre paths radiate out from each corner of the sail: tack, head, clew, cunningham, battens.

The great strength of this layout allows us to integrate curved fibres in the areas where we want the sail to be supple, and pre-stretched straight fibres where we want shape and no deformation. For this sail, we chose Kevlar® and Black Technora®, which we believe to be the best option for this race programme. The leech is reinforced with Spectra® fibres.

Luffs

Luffs

All our luffs are made in-house.

- A stiff bolt rope is used to prevent the luff from coming out of the luff track or groove.

- An extra band of Teflon is added to areas which are vulnerable to wear, for example at the feeder, the luff end of full-length battens and the halyard point.

Clew

- The clews of our inshore racing mainsails feature a stainless steel ring secured with webbing to spread the load equally, reinforced with hand-stitching, and an adjustable boom strop with spectra lashing

Tack and cunningham

- The tack and cunningham feature a ring secured with webbing to spread the load.

- The reinforcement in radiating fibres (twaron) keeps the shape longer at the tack. The fibres used here are the same as the fibres in the mainsail panels.

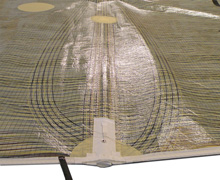

- All the fibres are meticulously laid out by our Trilam® manufacturer. The fibre layout exactly matches that produced by the design office.

Short battens

The battens In the mainsail are buried between 2 Trilam® panels. Here we can clearly see the different fibre layouts, which are curved or straight and correspond to the range of loads produced by the batten.

Along the leech, the leech line is led over the batten pocket. It is hidden in a protective lead to prevent it from catching in the runners or backstay.

Batten tensioning system

- All batten pockets feature a lashing system which is easily accessible to adjust the batten tension or to remove a broken batten.

- Our battens are tapered to match the shape defined by the design office.

Loose foot construction

- It is possible to add a loose foot in light material which adds a little surface area for downwind performance.

- There is an integrated stowage system so that it doesn’t flap upwind.

Tell us about your project : Contact us to request a quote