Expertise

All Purpose sails are truly “Made in France” by skilled sailmakers

Listen to the customer: sails designed in close collaboration with the end-user

The first essential step in designing a sail is to listen to the customer, share experience, and gain a thorough understanding of requirements. We are deeply committed to designing sails in close collaboration with our customers

Sail design softwares used by the design office

The design office dedicates a great deal of time to the design of sails with the help of specialist software tools:

-

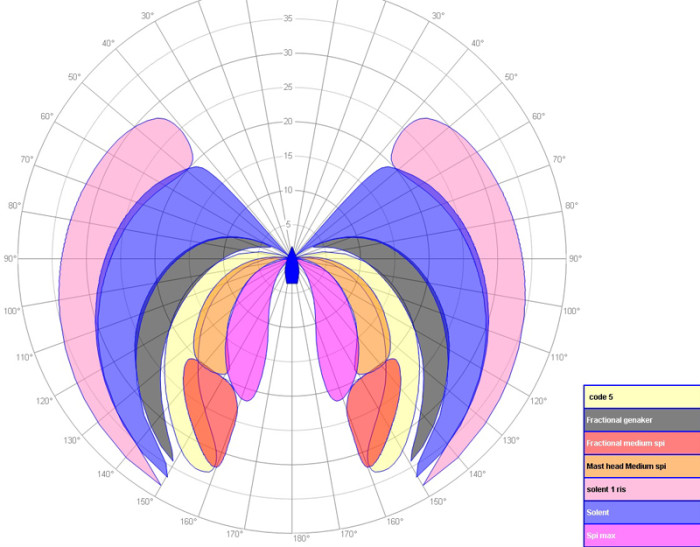

Sailect by Optima

Sailect by Optima is used in the pre-design stage to visualise the range of use of a particular sail, the wind angles and wind strength for which the sail needs to be designed.

Post-design, this software provides the sailor with reliable data and is used to validate options.

-

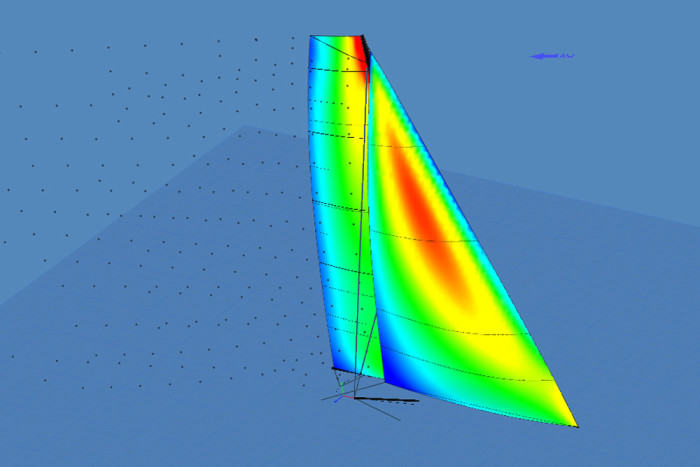

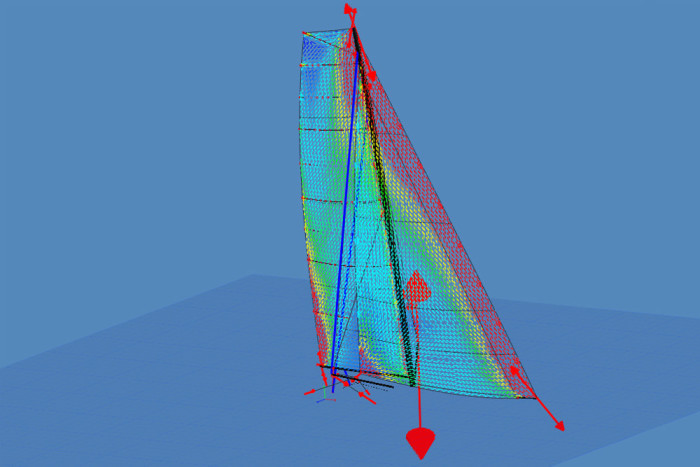

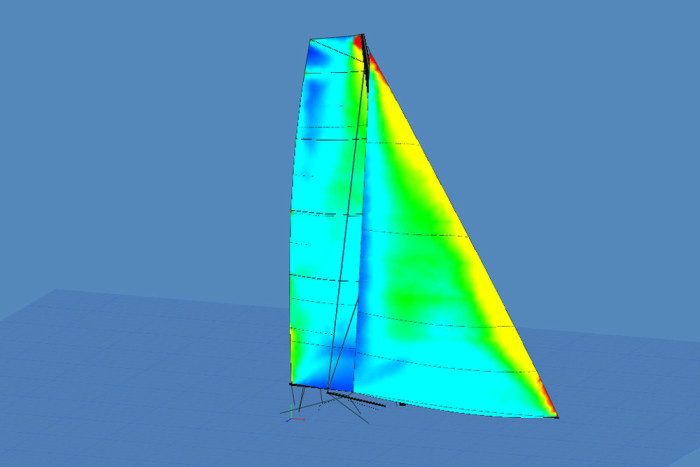

Logiciel Flow structure interaction by Aravanti

In 2016, All Purpose acquired FSI (Flow Structure Interaction) software from BSG Developpements. This software allows to simulate the aerodynamic flow in the sails, and therefore shows the deformation of the materials and calculates the load in the rigging.

-

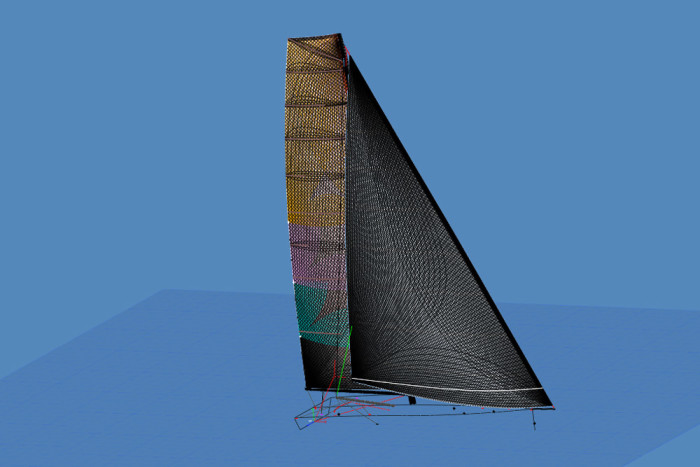

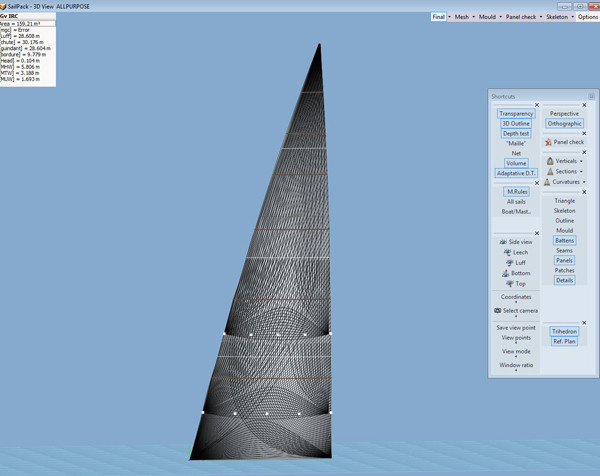

Sailpack Boat Module

Sailpack Module Bateau creates a realistic simulation of the boat, rig and rigging.

Together with FSI, it helps to define mast bend and optimise mainsail luff curve and geometry.

-

Sailpack shape 3D

This software allows designers to design a sail in 3D.

The designers at All Purpose are first and foremost experienced sailors. They all use the SailPack Sail Design software, leader in its field. There is a constant flow of information and experience between the design offices within the group, essential to producing the best possible sails.

Which fabric for which programme?

An in-depth analysis of goals and constraints, as well as the particular characteristics of each boat enables All Purpose to select the right materials. A mainsail can be composed of several different fabrics and numerous fibres.

There are three kinds of fabrics :

- woven

- unidirectional fibres

- multiaxial fibres such as Trilam® and TPI Trilam® Precontrain Isotrope

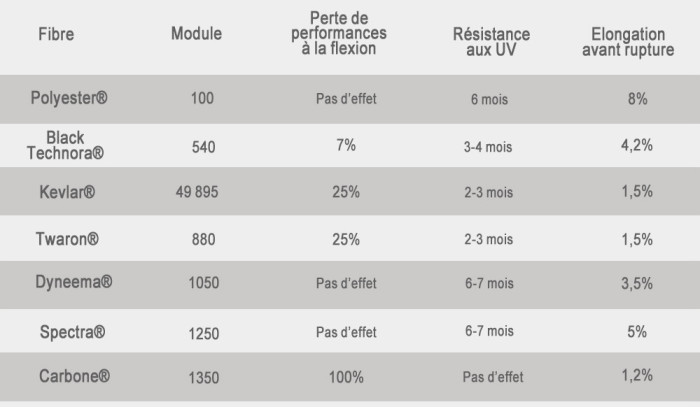

Fibres :

• Polyester : mainly used in cruising sails or racing sails where the type of fabric is restricted by the class rules.

• Kevar and Twaron (aramid) : sensitive to UV and flex. Often associated with UV and flex resistant fibers such as Black Technora or Dyneema

• Black Technora (aramid) coated for UV protection

• Dyneema / Spectra (high modulus polyethylenes). Good resistance to UV and flex, very strong and durable, tear-resistant. Creep sensitive (stretch under long-term load).

• Vectran. Liquid crystal polymer from the polyester family. Flex-resistant.

• Carbon. Very low flex resistance, therefore not particularly adapted to sailcloth.

Measurement :

All Purpose can visit your boat to take measurements. Download measurements sheets as follow :

Mainsail Mainsail with slides

Headsails Downwind sails

Download Sail Pack viewer

Ask your All Purpose sailmaker your sails'file to view them or color your spinnaker.