Inshore Racing Headsail assembly

High-tech manufacturing for optimal performance

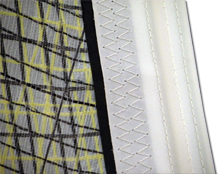

Luff

All our luffs are made in-house at the Carnac loft. We prefer them to the heat-glued ones which are more fragile and difficult to repair.

The photo shows a double cable luff: the first is a tight braid cable to prevent it coming out of the luff groove, and the second is a plastic rod. This double cable luff solution has been chosen to facilitate fast headsail hoists when mark n°3 is approaching at speed....

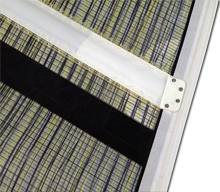

Full-length battens

At the luff, the full-length batten is enclosed in a plastic batten box which is screwed in place.

It is placed as close as possible to the luff so that the batten doesn’t drop off to leeward.

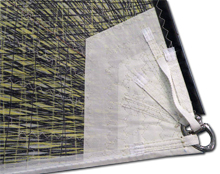

Clew

Clew

A stainless steel ring secured with webbing over 90° ensures that the loads are perfectly spread.

The leech line and foot line have an elastic tensioner which prevents them from catching on anything during the numerous manœuvres around the cans.

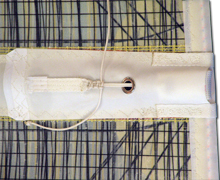

Tack

The tack is composed of a snap shackle which can be released under load. It is totally recessed into the sail to keep the foot of the sail close to the deck (deck effect).

A textile system (webbing strop or string depending on the type of shackle) facilitates releasing the shackle.

The webbing is secured with hand-stitching using waxed twine.

Battens

Battens are removable so that they can be removed for transport or if there is a breakage.

The lashing system is the preferred option over Velcro which has a tendency to slip over time.